We deliver fast - Postage free from 150 € (DE) - 60 days right of return - mail@bildhau.de - Tel.: +49 (0)221-99874700

Casting, coating, laminating, supporting with synthetic resin

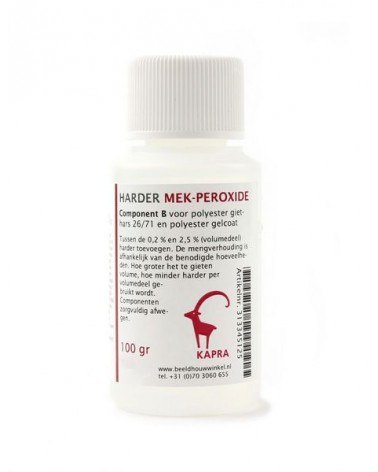

Synthetic resins are usually two-component systems consisting of the resin itself and a suitable hardener. After mixing, curing takes place through a chemical reaction in which heat is released (exothermic reaction). All synthetic resins available from bildhau cure at room temperature (20 °C). The room temperature and humidity in the working area can significantly influence the curing behaviour of the individual compounds. As a rule, the compounds should not be processed at temperatures below 15 °C; a temperature of around 18 °C to 25 °C is ideal so as not to disrupt the curing processes.

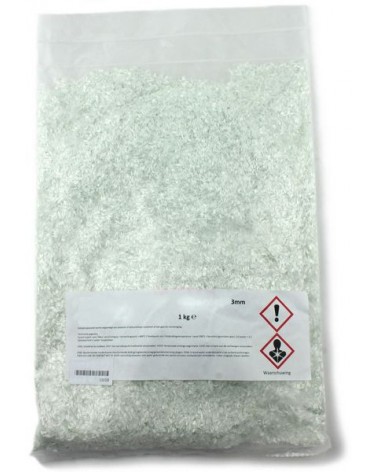

Synthetic resins include casting resins and gelcoats based on polyester resin , epoxy resin or polyurethane resin . Polyester resin and epoxy resin are transparent. Acrylic resin is also a synthetic resin, but has a plaster-like appearance. Instead of a hardener, a mineral powder is added to the acrylic resin. The synthetic resins have different properties and are therefore suitable for very different applications.

> read more